In the food and beverage industry, contamination is the enemy. With 55% of all food recalls attributed to biological, chemical, or foreign matter contamination, ensuring a hygienic environment is paramount. In 2023 alone, FDA food recall events increased by almost 20%. While most attention is placed on food contact surfaces, non-food contact areas—such as electrical raceways—are just as critical in preventing contamination risks. Are your electrical raceway systems designed to meet the highest sanitary standards, corrosion resistance, and reliability requirements?

Why Facilities Must Prioritize Hygienic Raceway Systems

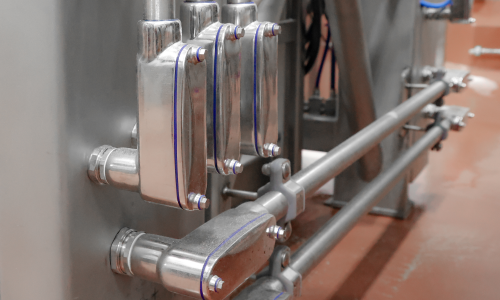

Moisture, high-pressure washdowns, and strict sanitation protocols demand more than just a standard conduit system. Traditional stainless electrical raceways with exposed threads, rough surfaces, and crevices can trap debris and harbor bacteria, making them difficult to clean and maintain. That’s where stainless-steel food grade conduit and fittings designed specifically for hygienic environments can provide a solution to help prevent contamination that can enter the food supply.

The Benefits of Hygienically Designed Stainless Steel Conduit in Food & Beverage Manufacturing

1. Superior Corrosion Resistance

The harsh cleaning agents and high-moisture environments present in food plants typically require the use of stainless-steel electrical raceway systems. Stainless steel raceway systems come in 304 or 316 stainless steel, offering mechanical strength and corrosion resistance. 304 stainless steel is highly durable and resistant to most chemicals, making it suitable for most industrial applications and food processing plants. 316 stainless steel contains molybdenum, which enhances its resistance to chlorides, acids, and harsh washdown environments, making it the preferred choice for extreme corrosive environments where hygiene and longevity are critical. However, in environments where hygiene is important, being constructed of stainless steel isn’t enough.

2. Seamless, Hygienic Design

In food processing and sanitary environments, hygiene is not just a priority—it’s a requirement, courtesy of the Food Safety Modernization Act, which was signed into law in 2011 and shifted the focus from responding to foodborne illness outbreaks to preventing them by focusing on the prevention of contamination throughout the food supply chain and facilities. Robroy Stainless Food Grade Electrical Raceway Systems are engineered to meet the highest sanitation standards, ensuring contaminant-free, corrosion-resistant, and easy-to-clean installations. Designed specifically for food and beverage production facilities, these raceway systems feature:

- An industry compliant platform of conduit and fittings designed for compliance in the food grade environment as an installed system.

- Seamless, crevice-free construction to eliminate bacterial harborage points.

- Optimized sealing with FDA-compliant blue silicone gaskets to prevent ingress of moisture and dust.

- Superior ingress protection with IEC IP69K rating for resistance against high-pressure, high-temperature washdowns.

- Patented hygienic designs that minimize flat surfaces that can lead to contaminant buildup and maximize cleanability for Food & Beverage facilities.

- Corrosion-resistant 304 or 316 stainless steel construction for strength and durability in harsh washdown environments.

- NSF certification, ensuring 3rd party compliance with strict food safety and sanitation standards.

- Oxidative Thermo Process marking to eliminate paper labels and reduce the risk of foreign matter contamination.

- Captive hex head screw retention system prevents loose hardware, risk of foreign matter contamination and maintain hygienic integrity.

- The Robroy hygienic symbol for easy identification of food-grade raceway components.

- No exposed threads or crevices where contaminants can hide.

- Electro-polished finishes that enhance cleanability and corrosion protection.

This advanced design ensures that every component contributes to a fully sanitary system, reducing contamination risks and ensuring compliance with food safety standards.

3. Ease of Cleaning and Maintenance

Food plants require rigorous sanitation protocols, including high-pressure and high-temperature washdowns. Robroy Food Grade stainless steel conduit and fittings are IP69K-rated as an installed system, meaning your installation can withstand direct, high-pressure sprays without compromising safety or performance. This level of ingress protection is essential for maintaining compliance with sanitary regulations and equipment reliability. This design enables the sanitation department to clean this area of your electrical infrastructure without compromise.

4. Regulatory Compliance and Food Safety Standards

Regulated (FDA, USDA) Food processing facilities must adhere to strict regulatory standards standards developed by as NSF, 3-A, BISSC, EHEDG to ensure food safety, sanitation and compliance with hygiene requirements. Robroy Stainless hygienic conduit and fittings are engineered, tested, and certified to meet the following applicable standards, making it easier for food manufacturers to ensure they have compliant raceways.

- NSF/ANSI/3-A 14159-1: A critical food safety standard for hygienic design of equipment used in food processing. Ensures materials are non-toxic, corrosion-resistant, and cleanable, with no harborage points for bacteria.

- IEC IP69K: Ensures equipment can withstand high-pressure (80 to 100 bar/1,160 to 1,450 PSI), high-temperature (176◦F / 80◦C) washdowns common in food processing environments.

- Type 4X: Ensures corrosion-resistant, sealed protection against moisture, chemicals, and high-pressure washdowns, making them essential for hygienic electrical installations in food processing environments.

- UL 6A: Ensures the conduit meets safety, durability, and strength criteria.

- UL 514B: Standard ensuring safety of fittings for use with cable and conduit intended for installation in accordance with the National Electrical Code, ANSI/NFPA 70, the Canadian Electrical Code (CEC), Part I, CSA C22.1, and the Standard for Electrical Installations, NOM-001-SEDE.

- UL 514A: Establishes safety requirements for metallic outlet boxes and other electrical components.

Using industry compliant food grade stainless-steel conduit and fittings systems reduces the risk of regulatory violations, fines, and costly shutdowns, ensuring a safe and sanitary production environment.

5. Long-Term Cost Savings and Durability

Investing in a hygienically designed stainless steel raceway system over a traditional stainless-steel raceway system provides significant long-term cost savings and durability in food processing environments. While both materials may offer corrosion resistance, hygienically designed systems eliminate harborage points, crevices, and exposed threads, reducing the risk of bacterial buildup and contamination. This minimizes cleaning time, decreases the need for aggressive chemical sanitization, and extends the lifespan of the system by preventing corrosion-related failures. Additionally, features like sealed connections, optimized gasket compression, and smooth, non-porous surfaces enhance washdown efficiency and reduce water usage, labor costs, and maintenance. Unlike traditional systems that may require frequent replacements, or retrofitting due to design flaws, a purpose-built food grade raceway system ensures long-term compliance, reducing downtime, increasing operational efficiency, and reduced total cost of ownership in food and beverage processing facilities. Most importantly, by preventing bacterial contamination and eliminating hidden risks, it also helps reduce the chance of costly product recalls that can damage brand reputation and disrupt operations.

The Importance of Hygiene and Safety in Food & Beverage Manufacturing

In food and beverage production, maintaining a clean and safe environment is crucial for preventing contamination and ensuring product integrity. Electrical raceway systems must be designed with hygienic principles in mind to minimize potential risks such as preventing microbial growth, reducing foreign matter contamination and meeting sanitation protocols.

Incorporating hygienic stainless steel raceways ensures a safer work environment, reduces contamination risks, and improves overall plant efficiency.

Future-Proofing Your Installations

Food processing facility managers must think ahead. As food safety regulations tighten, facilities will demand raceway systems that, as an installed system, are both hygienic and durable. By installing food grade stainless steel conduit and fittings from Robroy Stainless now, food manufacturers can stay ahead of compliance requirements while ensuring long-term reliability and safety.

Conclusion: The Smart Choice for Food-Grade Facilities

Food Grade Stainless Steel conduit and fittings are not just a trend, they are a necessity for modern food and beverage processing facilities. With benefits including superior corrosion resistance, seamless design, easy cleaning, regulatory compliance, durability, and long-term cost savings, stainless steel raceways correctly designed for the application are the smart investment for end-users and contractors looking to deliver high-quality, lasting solutions.