Robroy Stainless’ Food Grade Fittings are engineered to meet the most stringent sanitary requirements in industries where cleanliness is critical. Whether you're operating in food processing, pharmaceuticals, or any environment where contamination control is essential, our solution provides superior protection against bacterial buildup and corrosion.

Why Choose Our Robroy Stainless Food Grade System?

Engineered for Maximum Cleanability

Robroy Stainless is designed to meet the highest hygienic standards by eliminating contamination-prone areas and ensuring easy sanitation. Our innovative conduit body and raceway system feature:

- Patented hygienic conduit body and cover with a seamless design to prevent crevices where bacteria, moisture, and debris can accumulate.

- No flat surfaces, reducing the potential for food particles and moisture retention.

- Smooth, non-porous stainless steel construction that minimizes bacterial harborage and allows for efficient cleaning in washdown environments.

Optimized Sealing for Ultimate Protection

A fully sealed electrical system is critical for maintaining hygienic integrity. Robroy Stainless ensures superior environmental sealing with:

- FDA-compliant blue silicone gaskets (non-food color) that prevent moisture and debris ingress, maintaining a sanitary environment.

- Integrated mechanical stops, ensuring consistent gasket compression and reliable long-term sealing.

- Center-aligned threading and circular gasket system, providing a secure, contamination-free installation.

- IEC IP69K-rated protection, built to withstand high-pressure, high-temperature washdowns without compromising performance.

Designed to Minimize Foreign Matter Contamination

Foreign matter contamination is a major risk in food and pharmaceutical processing. Robroy Stainless mitigates this risk with:

- Oxidative Thermo Process (OTP) permanent marking instead of paper labels, preventing degradation and contamination over time.

- Captive screw retention and gasket system, eliminating loose components that could become a hazard in sanitary environments.

Easily Identifiable Hygienic Components

Our hygienic raceway components are built for quick identification and compliance with food safety standards, including:

- Compliance with major electrical listings, including UL, ensuring safety and reliability.

- NSF certification, confirming compliance with the strictest food safety and sanitary design standards.

- Distinctive Robroy Hygienic Symbol, making it easy for facility managers and installers to recognize raceway components specifically designed for clean environments.

Industries That Trust Robroy Stainless

Our hygienic raceway systems are trusted in industries where safety, cleanliness, and reliability are non-negotiable:

✔ Food & Beverage Processing – Supports FSMA and FDA requirements for sanitary installations.

✔ Pharmaceutical & Biotech – Supports cGMP compliance for cleanroom environments.

✔ Dairy & Beverage Manufacturing – Resists corrosive byproducts from dairy and fermentation processes.

✔ Meat & Poultry Production – Handles high-pressure washdowns and harsh cleaning agents.

How Our Food Grade Stainless Steel System Stands Out

Robroy Stainless eliminates contamination risks, enhances food safety compliance, and withstands the harshest sanitary conditions—all while simplifying installation and maintenance.

- Overall sealed system with a high degree of ingress protection against dust and high pressure / high temperature spray for added safety and sanitation within plant operations.

- Patented hygienic designed conduit body and cover maximizes cleanability and minimizes contaminate buildup of installed system.

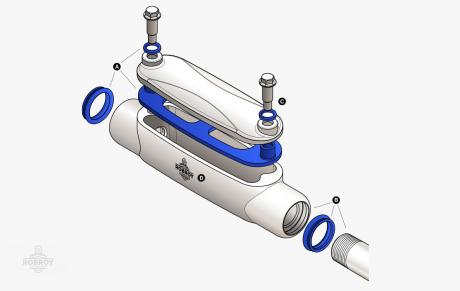

A: FDA Compliant blue (non-food color) silicone gasket with mechanical stops guarantees optimized compression for environmental ratings.

B: Center aligned threading of conduit and circular gasket ensures environmental and safety rating conformance of installed system.

C: Specially designed captive screw retention and gasket system eliminates risk of ingress and contamination.

D: Oxidative Thermo Process marking permanently marks product with no surface degradation, paper labels or stamped surfaces maximizing hygienic benefit.